In recent years, paramount demands for new products have incurred more product development activities. Among the various stages of product lifecycle, manufacturing processes are energy intensive making the stage one of the primary energy consumption and carbon footprint sources. Effective implementation of manufacturing sustainability and eco-design technologies is increasingly prevalent for companies. The lack of effective, efficient, knowledge-based intelligent services to evaluate, simulate, plan and optimise manufacturing energy consumption and carbon emission during design and manufacturing planning is a major barrier crippling both large Original Equipment Manufacturers (OEMs) and Small and Medium-sized Enterprises (SMEs) to implement sustainability fully. It is timely to develop and deploy Information and Communication Technologies (ICT)-embedded intelligent services for product developers/manufacturers.

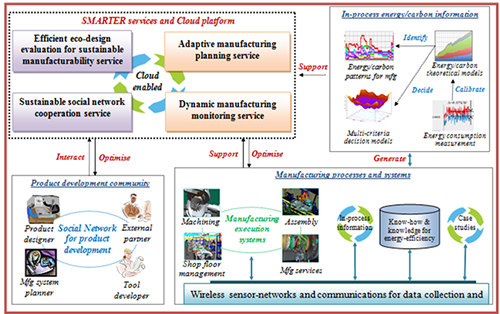

Funded by the EU Seventh Framework Programme (FP7), SMARTER (Sustainable Manufacturing Adaptive Services with Cloud Architectures for Enterprises) establishing effective industry-academia partnerships and pathways for sustainable manufacturing management by developing, deploying and demonstrating intelligent Cloud-based services (SMARTER services) to address dynamics and complexity in product development and manufacturing. The overall, project-level objectives include:

Objective 1: To team up and second intersectoral researchers to enrich knowledge bases and achieve research synergies in sustainable manufacturing by sharing the latest research on know-how, strategies, technologies and industrial case studies, and to provide cross-sectional engineering training to researchers to develop versatile and multi-disciplinary applied research skills;

Objective 2: To integrate and demonstrate the complementary expertise of the intersectoral teams to devise Cloud-based sustainability services and supporting platform. The services and platform will be developed through integration and further development of core technologies from academic and industrial partners, and verification by real-world case studies in product development and manufacturing. The services and supporting platform will address the multi-faceted requirements and dynamics of modern manufacturing;

Objective 3: To showcase as real-world shop-floor demonstrators deployed in various venues of European industries and research institutes for technical demonstration, promotion and adoption; and to organise knowledge sharing and outreach activities for relevant communities and stakeholders in wider regions of the EU to increase the awareness of the project outcomes and to exploit the proposed solutions in order for EU manufacturers to shift towards sustainability efficiently.

The project Consortium is comprised of 8 partners (3 research universities, 1 research centre, 1 multi-national manufacturing company, 1 large energy/carbon technical consultancy company, and 2 SME companies related to manufacturing simulation and energy/carbon-related product development) from 4 European countries (UK, Sweden, Germany and Spain). The complementary expertise of the academic and industrial European partners in the project enables effective knowledge sharing, dissemination and exploitation of scientific and technical know-how, findings, and industrial applications across the EU.

Comments are disabled